FSMD1206

|

Surface Mount

PPTC - FSMD2920 Series

|

|

|

|

※ RoHS Compliant / (Lead Free) Available

|

|

|

|

|

Application:

|

All high-density

boards

|

|

Product Features:

|

2920 Dimension, Surface mountable,

Solid state,

Faster time to trip than standard SMD

devices.

|

|

Operation Current:

|

300mA~3.0A

|

|

Maximum Voltage:

|

6V~60VDC

|

|

Temperature Range:

|

-40°C to 85°C

|

|

Agency Recognition:

|

UL (E211981),

C_UL

(E211981),

*TÜV (R50090556)

|

|

|

|

|

|

|

|

|

|

|

|

Part

Number

|

Hold

Current

|

Trip

Current

|

Rated

Voltage

|

Maximum

Current

|

Typical

Power

|

Max Time to Trip

|

Resistance

|

|

RMIN

|

R1MAX

|

|

IH, A

|

IT, A

|

VMAX,Vdc

|

IMAX, A

|

Pd, W

|

Current

|

Time, S

|

ohms

|

ohms

|

|

FSMD030-2920

|

0.30

|

0.60

|

60

|

10

|

1.5

|

1.5

|

3.0

|

1.00

|

4.80

|

|

FSMD030-2920-R

|

0.30

|

0.60

|

60

|

10

|

1.5

|

1.5

|

3.0

|

1.00

|

4.80

|

|

FSMD050-2920

|

0.50

|

1.00

|

60

|

10

|

1.5

|

2.5

|

4.0

|

0.30

|

1.40

|

|

FSMD050-2920-R

|

0.50

|

1.00

|

60

|

10

|

1.5

|

2.5

|

4.0

|

0.30

|

1.40

|

|

FSMD075-2920

|

0.75

|

1.50

|

33

|

40

|

1.5

|

8.0

|

0.3

|

0.18

|

1.00

|

|

FSMD075-2920-R

|

0.75

|

1.50

|

33

|

40

|

1.5

|

8.0

|

0.3

|

0.18

|

1.00

|

|

FSMD100-2920

|

1.10

|

2.20

|

33

|

40

|

1.5

|

8.0 8.0

|

0.5

|

0.09

|

0.41

|

|

FSMD100-2920-R

|

1.10

|

2.20

|

33

|

40

|

1.5

|

8.0 8.0

|

0.5

|

0.09

|

0.41

|

|

FSMD125-2920

|

1.25

|

2.50

|

33

|

40

|

1.5

|

8.0

|

2.0

|

0.05

|

0.25

|

|

FSMD125-2920-R

|

1.25

|

2.50

|

33

|

40

|

1.5

|

8.0

|

2.0

|

0.05

|

0.25

|

|

FSMD150-2920

|

1.50

|

3.00

|

33

|

40

|

1.5

|

8.0

|

2.0

|

0.05

|

0.23

|

|

FSMD150-2920-R

|

1.50

|

3.00

|

33

|

40

|

1.5

|

8.0

|

2.0

|

0.05

|

0.23

|

|

FSMD185-2920

|

1.85

|

3.70

|

33

|

40

|

1.5

|

8.0

|

2.5

|

0.04

|

0.15

|

|

FSMD185-2920-R

|

1.85

|

3.70

|

33

|

40

|

1.5

|

8.0

|

2.5

|

0.04

|

0.15

|

|

FSMD200-2920

|

2.00

|

4.00

|

16

|

40

|

1.5

|

8.0 8.0

|

4.5

|

0.035

|

0.120

|

|

FSMD200-2920-R

|

2.00

|

4.00

|

16

|

40

|

1.5

|

8.0 8.0

|

4.5

|

0.035

|

0.120

|

|

FSMD250-2920

|

2.50

|

5.00

|

16

|

40

|

1.5

|

8.0

|

16

|

0.025

|

0.085

|

|

FSMD250-2920-R

|

2.50

|

5.00

|

16

|

40

|

1.5

|

8.0

|

16

|

0.025

|

0.085

|

|

FSMD260-2920

|

2.60

|

5.20

|

6

|

40

|

1.5

|

8.0

|

20.0

|

0.020

|

0.075

|

|

FSMD260-2920-R

|

2.60

|

5.20

|

6

|

40

|

1.5

|

8.0

|

20.0

|

0.020

|

0.075

|

|

FSMD300-2920

|

3.00

|

5.20

|

6

|

40

|

1.5

|

8.0

|

25.0

|

0.015

|

0.048

|

|

FSMD300-2920-R

|

3.00

|

5.20

|

6

|

40

|

1.5

|

8.0

|

25.0

|

0.015

|

0.048

|

|

|

|

|

IH=Hold current-maximum current at which

the device will not trip at 23°C still air.

IT=Trip current-minimum current at which the device

will always trip at 23°C still air.

V MAX=Maximum voltage device can withstand without

damage at its rated current.

I MAX=

Maximum fault current device can withstand without damage at rated

voltage (V max).

Pd=Typical power

dissipated from device when in the tripped state in 23°C still air

environment.

RMIN=Minimum device

resistance at 23°C.

R1MAX=Maximum device

resistance at 23°C, 1 hour after tripping .

Termination pad

characteristics

Termination pad materials: Tin-plated copper

*

Note: (1) FSMD300-2920: TÜV Pending

|

|

|

|

|

|

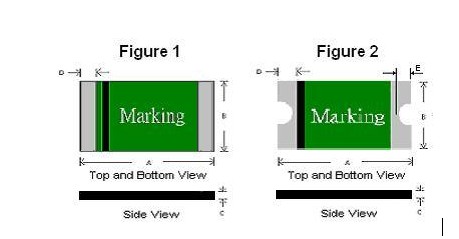

Part

Number

|

Fig.

|

A

|

B

|

C

|

D

|

|

Min

|

Max

|

Min

|

Max

|

Min

|

Max

|

Min

|

|

FSMD030-2920

|

1

|

6.73

|

7.98

|

4.80

|

5.44

|

0.60

|

1.15

|

0.35

|

|

FSMD030-2920-R

|

2

|

6.73

|

7.98

|

4.80

|

5.44

|

0.60

|

1.15

|

0.35

|

|

FSMD050-2920

|

1

|

6.73

|

7.98

|

4.80

|

5.44

|

0.60

|

1.15

|

0.35

|

|

FSMD050-2920-R

|

2

|

6.73

|

7.98

|

4.80

|

5.44

|

0.60

|

1.15

|

0.35

|

|

FSMD075-2920

|

1

|

6.73

|

7.98

|

4.80

|

5.44

|

0.40

|

1.15

|

0.35

|

|

FSMD075-2920-R

|

2

|

6.73

|

7.98

|

4.80

|

5.44

|

0.40

|

1.15

|

0.35

|

|

FSMD100-2920

|

1

|

6.73

|

7.98

|

4.80

|

5.44

|

0.40

|

1.00

|

0.35

|

|

FSMD100-2920-R

|

2

|

6.73

|

7.98

|

4.80

|

5.44

|

0.40

|

1.00

|

0.35

|

|

FSMD125-2920

|

1

|

6.73

|

7.98

|

4.80

|

5.44

|

0.40

|

0.90

|

0.35

|

|

FSMD125-2920-R

|

2

|

6.73

|

7.98

|

4.80

|

5.44

|

0.40

|

0.90

|

0.35

|

|

FSMD150-2920

|

1

|

6.73

|

7.98

|

4.80

|

5.44

|

0.40

|

0.90

|

0.35

|

|

FSMD150-2920-R

|

2

|

6.73

|

7.98

|

4.80

|

5.44

|

0.40

|

0.90

|

0.35

|

|

FSMD185-2920

|

1

|

6.73

|

7.98

|

4.80

|

5.44

|

0.30

|

0.90

|

0.35

|

|

FSMD185-2920-R

|

2

|

6.73

|

7.98

|

4.80

|

5.44

|

0.30

|

0.90

|

0.35

|

|

FSMD200-2920

|

1

|

6.73

|

7.98

|

4.80

|

5.44

|

0.30

|

0.90

|

0.35

|

|

FSMD200-2920-R

|

2

|

6.73

|

7.98

|

4.80

|

5.44

|

0.30

|

0.90

|

0.35

|

|

FSMD250-2920

|

1

|

6.73

|

7.98

|

4.80

|

5.44

|

0.30

|

0.90

|

0.35

|

|

FSMD250-2920-R

|

2

|

6.73

|

7.98

|

4.80

|

5.44

|

0.30

|

0.90

|

0.35

|

|

FSMD260-2920

|

1

|

6.73

|

7.98

|

4.80

|

5.44

|

0.30

|

0.90

|

0.35

|

|

FSMD260-2920-R

|

2

|

6.73

|

7.98

|

4.80

|

5.44

|

0.30

|

0.90

|

0.35

|

|

FSMD300-2920

|

1

|

6.73

|

7.98

|

4.80

|

5.44

|

0.30

|

0.90

|

0.35

|

|

FSMD300-2920-R

|

2

|

6.73

|

7.98

|

4.80

|

5.44

|

0.30

|

0.90

|

0.35

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A

=FSMD030-2920/-R

B

=FSMD050-2920/-R

C

=FSMD075-2920/-R

D

=FSMD100-2920/-R

E

=FSMD125-2920/-R

F

=FSMD150-2920/-R

G

=FSMD185-2920/-R

H

=FSMD200-2920/-R

I =

FSMD250-2920/-R

J =

FSMD260-2920/-R

K=

FSMD300-2920/-R

|

|

|

|

|

|

|

|

|

|

|

|

P/N

|

Pcs /Bag

|

Reel/Tape

|

|

FSMD030-2920/-R

|

-----

|

2K

|

|

FSMD050-2920/-R

|

-----

|

2K

|

|

FSMD075-2920/-R

|

-----

|

2K

|

|

FSMD100-2920/-R

|

-----

|

2K

|

|

FSMD125-2920/-R

|

-----

|

2K

|

|

FSMD150-2920/-R

|

-----

|

2K

|

|

|

|

P/N

|

Pcs /Bag

|

Reel/Tape

|

|

FSMD185-2920/-R

|

-----

|

2K

|

|

FSMD200-2920/-R

|

-----

|

2K

|

|

FSMD250-2920/-R

|

-----

|

2K

|

|

FSMD260-2920/-R

|

-----

|

2K

|

|

FSMD300-2920/-R

|

-----

|

2K

|

|

|

|

|

|

Warning:

|

-

Operation beyond the specified maximum ratings or

improper use may result in damage and possible electrical

arcing and/or flame.

-

PPTC device are intended for occasional overcurrent

protection. Application for repeated overcurrent condition

and/or prolonged trip are not anticipated.

-

Avoid contact of PPTC device with chemical solvent.

Prolonged contact will damage the device performance.

|

|

|

|

|

|

Pad

Layouts, Solder Reflow and Rework

Recommendations

The dimension in the table below

provide the recommended pad layout for each FSMD1812

device

|

|

|

|

Pad dimensions (millimeters)

|

|

Device

|

A

|

B

|

C

|

|

Nominal

|

Nominal

|

Nominal

|

|

All 2920 Series

|

5.10

|

2.30

|

5.60

|

|

|

Solder

reflow

|

Profile Feature

|

Pb-Free Assembly

|

|

Average Ramp-Up Rate (Tsmax to

Tp)

|

3 ℃/second max.

|

|

Preheat :

Temperature Min (Tsmin)

Temperature Max (Tsmax)

|

150 ℃

200 ℃

60-180 seconds

|

|

Time maintained above:

Temperature(TL)

|

217 ℃

60-150 seconds

|

|

Peak/Classification Temperature(Tp)

:

|

260 ℃

|

|

Time within 5℃ of actual Peak :

|

20-40 seconds

|

|

Ramp-Down Rate :

|

6 ℃/second max.

|

|

Time 25 ℃ to Peak Temperature

:

|

8

minutes max.

|

Note 1:

All temperatures refer to of the package,

measured on the package body

surface.

|

|

Solder

reflow

※ Due to

“Lead Free” nature, Temperature and Dwelling time for the

soldering zone is higher than those for Regular. This may

cause damage to other components.

1. Recommended max past thickness > 0.25mm.

2. Devices can be cleaned using standard methods and

aqueous solvent.

3. Rework use standard industry practices.

4. Storage Environment : < 30℃ /

60%RH

Caution:

1. If reflow temperatures exceed the recommended profile,

devices may not meet the performance requirements.

2. Devices

are not designed to be wave soldered to the bottom side of the

board.

|

|

|

|

|

|

|

|

|